SORTING DEVICES

SORTING DEVICES

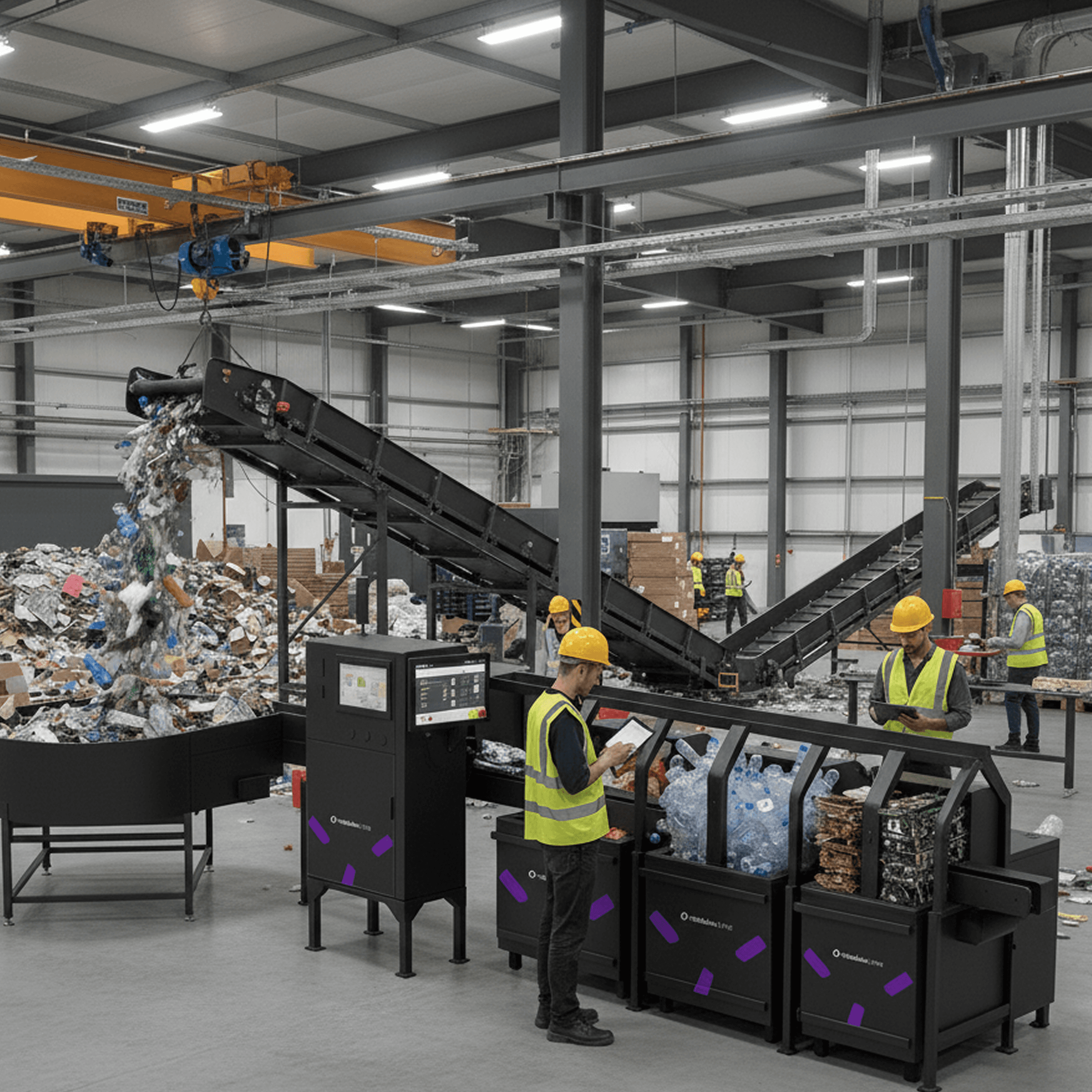

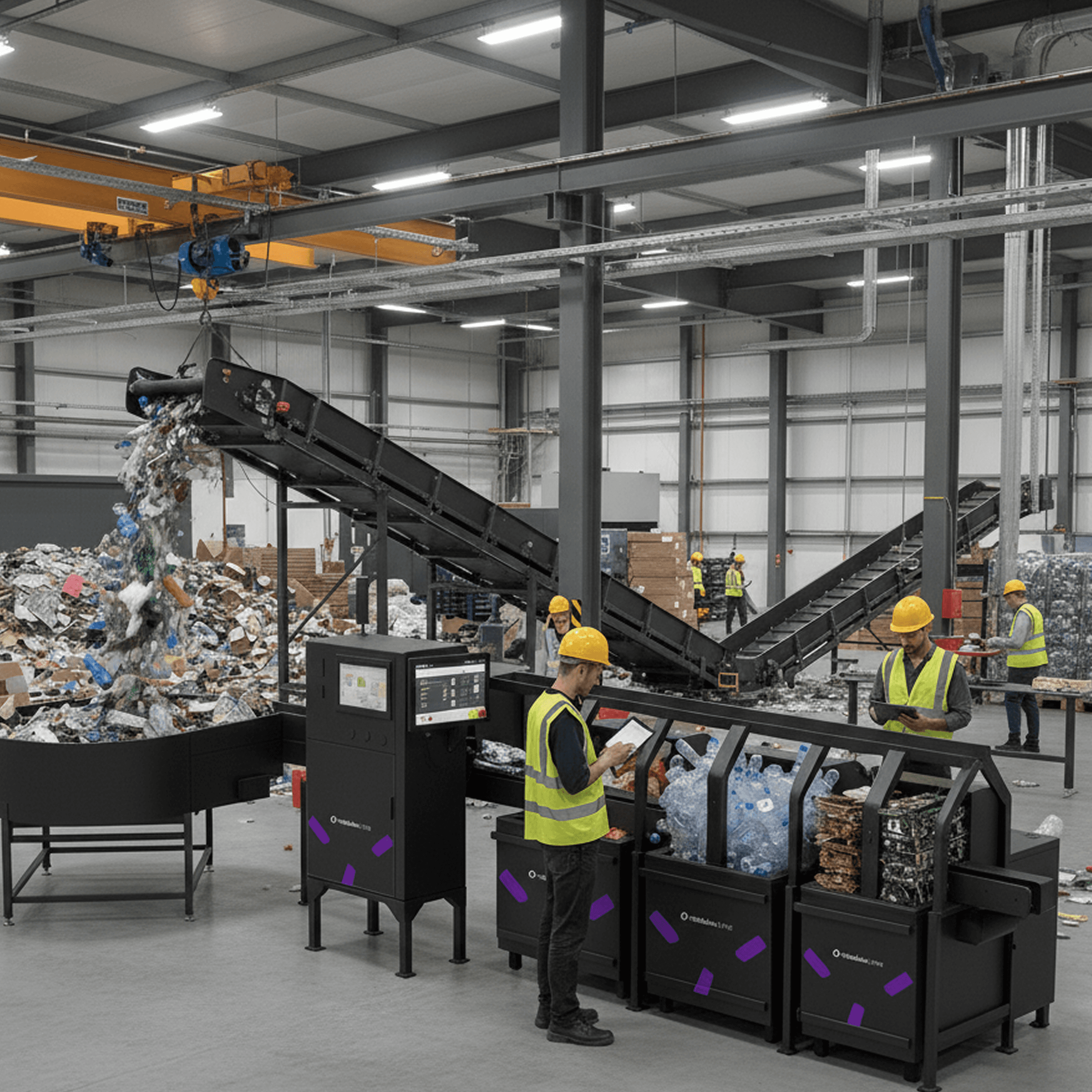

AI-Powered Sorting for the Future of Recycling

AI-Powered Sorting for the Future of Recycling

High-speed, high-accuracy detection and sorting of recyclables designed for industrial waste aggregators operating at scale.

Reklaim Line - Smart Sorting at Scale

Reklaim Line - Smart Sorting at Scale

AI-Driven Accuracy

Detects recyclables by colour, brand, size, cleanliness, and conditionProcessing Speed

Handles 200 items per minute (1.92 tons per 8-hour shift).High Precision

95% AI accuracy in mixed waste streamsMaterial Coverage

PET, metal, glass, rigid & flexible plasticsScalable EfficiencyUp to 8 stations for simultaneous multi-material sorting

Made in India. Built for the World.

Made in India. Built for the World.

Patented design and AI technology tailored for recyclers operating at industrial scale.

Built for Industrial Waste Aggregators & High-Volume Recyclers

Built for Industrial Waste Aggregators & High-Volume Recyclers

Reklaim Line transforms manual sorting with automated intelligence that:

Accelerates throughput, improving tons processed per shift

Reduces costs by optimising labour and resource allocation

Enhances procurement with quality-driven, traceable output

Performance That Adapts to Every Challenge

Performance That Adapts to Every Challenge

Engineered for Harsh Environments

Share Requirement

Operates in hot & humid conditions up to 60°C

Handles Massive Volumes

Designed for continuous, heavy-duty sorting

Half the Time, Double the Output

High-speed sorting ensures maximum ROI

Use and Retain the Packaging

fter consumption, the empty packaging is kept for return.

Receive Instant Refund

The deposit amount is transferred directly to the consumer’s chosen payment method.

Condition-Based Recognition

Share Requirement

Sorts based on ANY condition be it dirty, crushed, partially damaged, or clean

Multi-Parameter Sorting

Quality check across 8 different parameters simultaneously

End-to-End Traceability

Every item digitally recorded for reporting and compliance

Use and Retain the Packaging

fter consumption, the empty packaging is kept for return.

Receive Instant Refund

The deposit amount is transferred directly to the consumer’s chosen payment method.

Frequently Asked Questions

Frequently Asked Questions

Get quick answers to your most pressing questions

Get quick answers to your most pressing questions

What makes Reklaim Line different from traditional sorting machines?

Reklaim Line goes beyond mechanical sorting by using AI-powered vision technology. It doesn’t just identify materials but it also analyses colour, brand, size, cleanliness, and condition, ensuring 95% accuracy even in mixed or contaminated waste streams.

What types of materials can Reklaim Line process?

It handles a wide range of recyclables including PET bottles, metals, glass, rigid plastics, and flexible plastics. Its AI models can be updated to adapt to new material categories as your operations grow.

How fast is the sorting process?

Reklaim Line sorts 200 items per minute, equivalent to 1.92 tons per 8-hour shift, and can scale up to 8 stations for simultaneous, multi-material processing.

Can Reklaim Line work in challenging environments?

Yes. It’s engineered for harsh industrial conditions, capable of operating in hot and humid environments up to 60°C while maintaining consistent performance.

How accurate is the AI sorting?

The AI models achieve 95% accuracy, significantly reducing contamination rates and increasing the value of your recovered materials.

Does Reklaim Line reduce operational costs?

Absolutely. By automating manual sorting, it helps you: Lower labour dependency Increase throughput Optimise procurement with quality-driven outputs Improve ROI with faster cycle times

Is Reklaim Line scalable for growing operations?

Yes. The modular design supports up to 8 simultaneous sorting stations, allowing you to expand capacity as your recycling volumes increase.

How does Reklaim Line ensure traceability?

Every item sorted is digitally recorded, enabling end-to-end reporting, compliance documentation, and quality assurance. This makes it easier to meet regulatory standards and brand requirements.

Is Reklaim Line suitable for both small and large recyclers?

It is primarily designed for industrial waste aggregators and high-volume recyclers. However, modular deployment allows for customised setups depending on operational size and budget.

Where is Reklaim Line manufactured?

Reklaim Line is made in India for the world by combining patented local innovation with global recycling standards.

What makes Reklaim Line different from traditional sorting machines?

Reklaim Line goes beyond mechanical sorting by using AI-powered vision technology. It doesn’t just identify materials but it also analyses colour, brand, size, cleanliness, and condition, ensuring 95% accuracy even in mixed or contaminated waste streams.

What types of materials can Reklaim Line process?

It handles a wide range of recyclables including PET bottles, metals, glass, rigid plastics, and flexible plastics. Its AI models can be updated to adapt to new material categories as your operations grow.

How fast is the sorting process?

Reklaim Line sorts 200 items per minute, equivalent to 1.92 tons per 8-hour shift, and can scale up to 8 stations for simultaneous, multi-material processing.

Can Reklaim Line work in challenging environments?

Yes. It’s engineered for harsh industrial conditions, capable of operating in hot and humid environments up to 60°C while maintaining consistent performance.

How accurate is the AI sorting?

The AI models achieve 95% accuracy, significantly reducing contamination rates and increasing the value of your recovered materials.

Does Reklaim Line reduce operational costs?

Absolutely. By automating manual sorting, it helps you: Lower labour dependency Increase throughput Optimise procurement with quality-driven outputs Improve ROI with faster cycle times

Is Reklaim Line scalable for growing operations?

Yes. The modular design supports up to 8 simultaneous sorting stations, allowing you to expand capacity as your recycling volumes increase.

How does Reklaim Line ensure traceability?

Every item sorted is digitally recorded, enabling end-to-end reporting, compliance documentation, and quality assurance. This makes it easier to meet regulatory standards and brand requirements.

Is Reklaim Line suitable for both small and large recyclers?

It is primarily designed for industrial waste aggregators and high-volume recyclers. However, modular deployment allows for customised setups depending on operational size and budget.

Where is Reklaim Line manufactured?

Reklaim Line is made in India for the world by combining patented local innovation with global recycling standards.

What makes Reklaim Line different from traditional sorting machines?

Reklaim Line goes beyond mechanical sorting by using AI-powered vision technology. It doesn’t just identify materials but it also analyses colour, brand, size, cleanliness, and condition, ensuring 95% accuracy even in mixed or contaminated waste streams.

What types of materials can Reklaim Line process?

It handles a wide range of recyclables including PET bottles, metals, glass, rigid plastics, and flexible plastics. Its AI models can be updated to adapt to new material categories as your operations grow.

How fast is the sorting process?

Reklaim Line sorts 200 items per minute, equivalent to 1.92 tons per 8-hour shift, and can scale up to 8 stations for simultaneous, multi-material processing.

Can Reklaim Line work in challenging environments?

Yes. It’s engineered for harsh industrial conditions, capable of operating in hot and humid environments up to 60°C while maintaining consistent performance.

How accurate is the AI sorting?

The AI models achieve 95% accuracy, significantly reducing contamination rates and increasing the value of your recovered materials.

Does Reklaim Line reduce operational costs?

Absolutely. By automating manual sorting, it helps you: Lower labour dependency Increase throughput Optimise procurement with quality-driven outputs Improve ROI with faster cycle times

Is Reklaim Line scalable for growing operations?

Yes. The modular design supports up to 8 simultaneous sorting stations, allowing you to expand capacity as your recycling volumes increase.

How does Reklaim Line ensure traceability?

Every item sorted is digitally recorded, enabling end-to-end reporting, compliance documentation, and quality assurance. This makes it easier to meet regulatory standards and brand requirements.

Is Reklaim Line suitable for both small and large recyclers?

It is primarily designed for industrial waste aggregators and high-volume recyclers. However, modular deployment allows for customised setups depending on operational size and budget.

Where is Reklaim Line manufactured?

Reklaim Line is made in India for the world by combining patented local innovation with global recycling standards.